Industry Overview:

ELECTRONIC & INDUSTRIAL ENCLOSURES

High performance electronics have safety requirements unlike any other equipment. The slightest vibration, jolt or shift in temperature can affect performance or even do a device serious damage. Experts know it's important to carefully enclose these devices, to protect it and ensure the device's reliable operation for years to come.

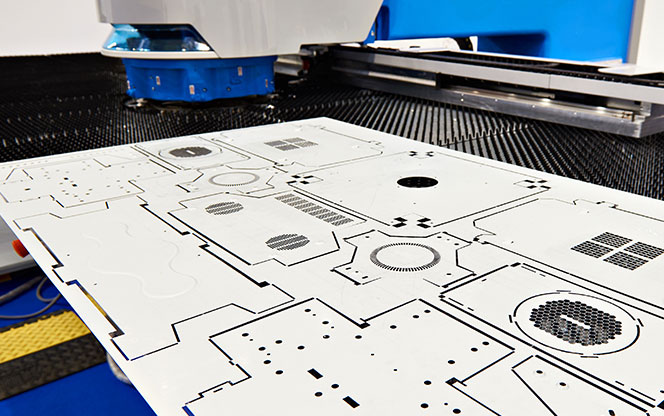

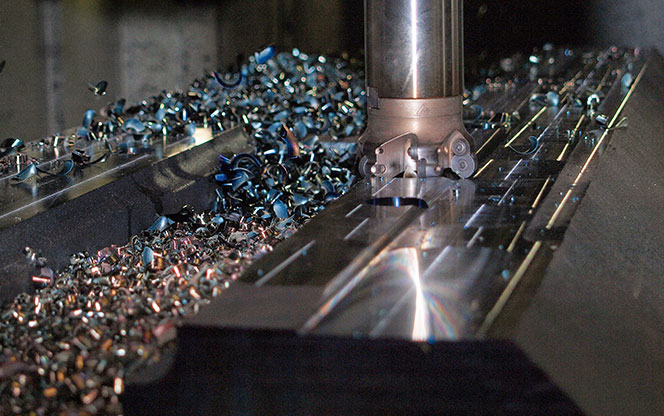

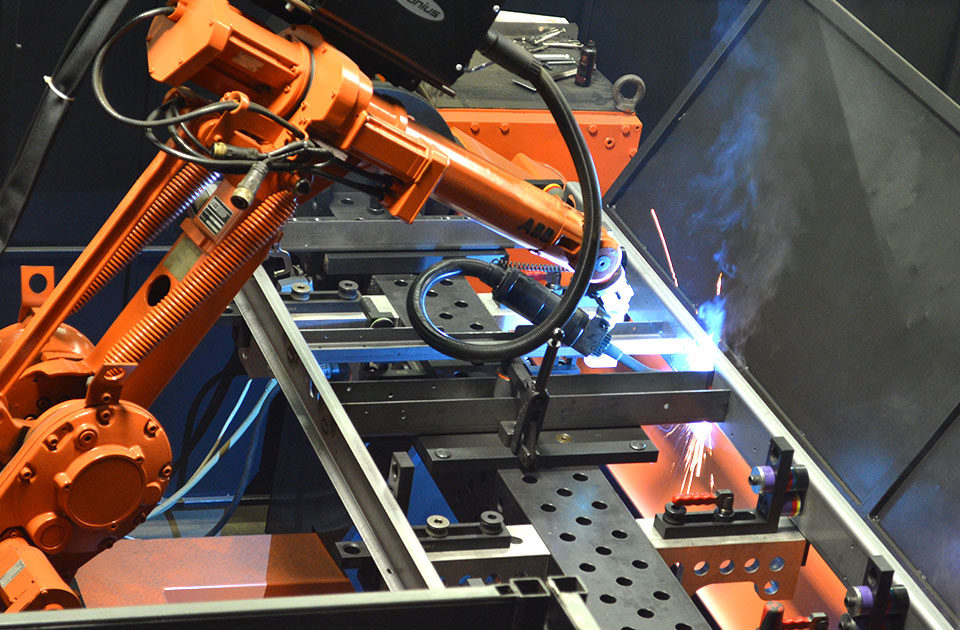

As you might expect, a normal box just won't cut it. Companies, researchers and government stakeholders rely on Mac Metal to create metal electronic and industrial enclosures that meet the specific needs for their devices. Our laser cutting, robotic and certified human welding techniques, and expert design teams, work together to make an enclosure that will protect even the most delicate equipment.

REQUEST A QUOTE TODAY:

Please fill out the form below to start your quote or give us a call at 262.251.4890RECENT ARTICLES

January 19, 2023

Mac Metal, a Wisconsin-based leading metal fabricator of high-quality weldments and metal products, has successfully obtained the ISO 9001:2015 certification of its Manufacture and Assembly of […]

March 9, 2022

Nearly four years ago, Mac Metal bought its first fiber laser – giving us the ability to cut a wide array of materials faster and with […]

July 24, 2018

If you’re in need of metal fabrication, it’s beneficial to learn the pros and cons of robotic and manual welding. They both have advantages and disadvantages, […]