We Know Metal

EQUIPMENT LIST

High-quality metal components don’t just make themselves – they’re fabricated by craftsmen using latest state-of-the-art equipment and time-tested techniques. At Mac Metal, we have the equipment needed to fabricate metal projects of almost every size and shape, with in-house specialists who possess the expertise required to get the job done right – on time and on budget.

Quick Links:

Shearing / Cutting | Laser Cutting | Laser / Punch | Punching | Machining | Forming | Robotic Welding | Welding | Misc. Fabricating | Measurement and Testing | General Equipment | Shipping

Shearing / Cutting | Laser Cutting | Laser / Punch | Punching | Machining | Forming | Robotic Welding | Welding | Misc. Fabricating | Measurement and Testing | General Equipment | Shipping

Shearing / Cutting

- 1/4” x 10’ Cincinnati Square Shear with Automec CNC programmable front gauge, 48” power back gauge and conveyor – stacker

- Marvel 380A – w/ auto index capability

- 90 ton iron worker with bar shear, angle shear & punch

- 75 ton iron worker with shear/punch, flat, bar, angle & tube

Laser Cutting

- Amada LCG Fiber Laser

- 6000 watt fiber optic

- Equipped with automation

- 60 x 120 work envelope

- Amada Ensis Fiber Laser

- 9000 watt

- Cycle load automation system

- Fully Automated (1) Mazak Laser Cell

- (1) 2500 Watt CO2 lasers

- Fully automated with load / unload

- Both lasers w/ 60 x 120 work envelope

Laser / Punch

- Amada Apelio III 357 Vipros Series

- 2000 Watt laser combined with a 33 ton turret press

- Hydraulic ram with programmable stroke

- 50 x 144 sheet size with repositioning

Punching

- Turret Presses (4): All of our turret presses are 33 ton x 1/4” capacity and feature auto index for contour punching.

- Amada Pega # 358S 50” x 78” sheet size (50” x 156” with repositioning)

- (4) Auto Index stations

- Amada Pega # 367 60” x 72” sheet sizes (60” x 144” with repositioning)

- (3) Amada Pega # 357 50” x 72” sheet sizes (50” x 144” with repositioning)

- Amada Pega # 358S 50” x 78” sheet size (50” x 156” with repositioning)

- Punch Presses:

- Strippit #30-40 HD – 40 ton capacity with Creonics CNC gauging

- 125 ton Johnson mechanical O.B.I.

- 50 ton Niagra mechanical Str. Side

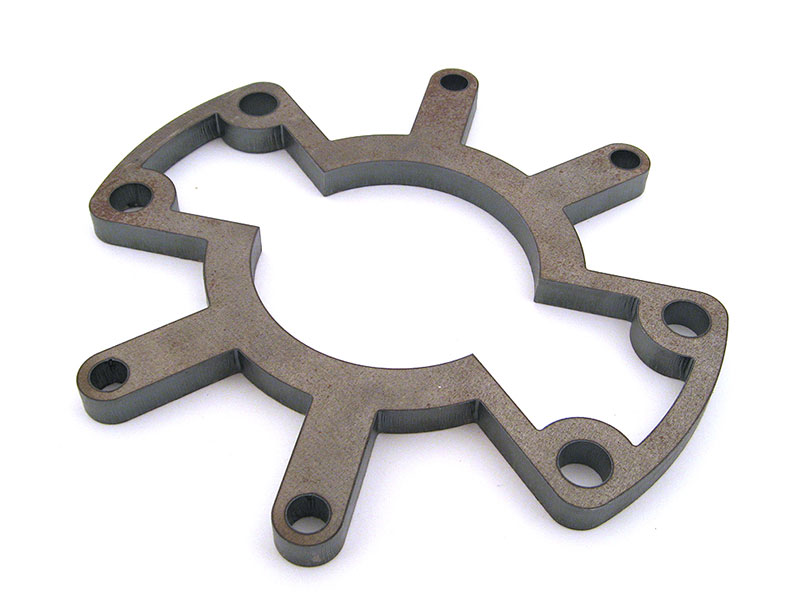

Machining

- (2) Haas VF4 Vertical Machining Center

- 50” x 20” x 24” work envelope

- Through spindle coolant

- Programmable coolant nozzle

- Equipped with Intuitive Probing System by Renishaw

- 50” x 20” x 24” work envelope

Forming

- Press Brakes:

- 65 Ton x 8’ Pacific w/ 3-axis CNC gauging

- 350 ton x 14’ Cincinnati Hydraulic w/ 6 axis back gauge Front gauge system

- 200 ton x 12’ Pacific Hydraulic with 2 axis CNC back gauge 48” range

- (2) 175 ton x 10’ Autoform by Cincinnati with 3-axis

CNC back gauge - 175 ton x 10’ Cincinnati CBII with 3 axis CNC gauge, with 14” stroke

- (1) 135 ton x 10’ Cincinnati CBII with 3 axis CNC gauge, with 14” stroke

- 90 ton x 8’ Cincinnati CBII with 3 axis CNC gauge, with 14” stroke

- 28 ton x 28” Toyokoki All electric brake press, with 2 axis CNC back gauge

- Other Forming:

- 4’ x 4” Bending Roll – 12 ga x 4’ capacity

- 6’ x 7” Bending Roll – 1/4” x 6’ capacity

- 18” Urethane (2) roll forming system 7 ga capacity

- #4 Diacro rotary bender

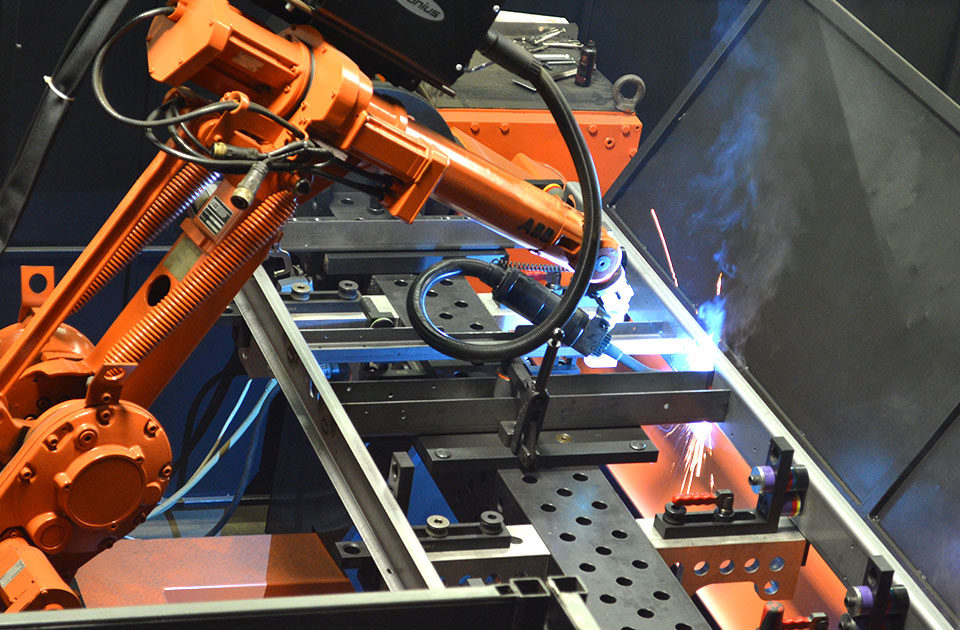

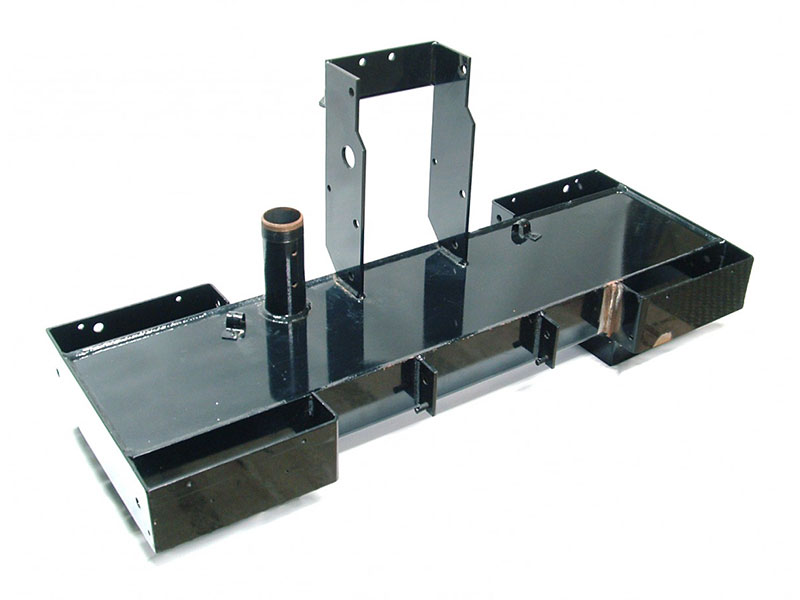

Robotic Welding

- (2) Wolf Robotics leanarc 500C system

- ABB IRB2400L robot

- Orbit 500C indexing positioner with 500 kg capacity per side

- Miller AutoAxcess 450 power source

- Through arc seamtracking and touch sensing

Welding

- (5) new TPS 320i Fronius MIG Welders

- New Fronius Flex Track welding system – equipped with TPS 450i Fronius welder

- New Tank Welding system with positioner

- (20) 350-450 amp Fronius & Miller M.I.G. Welders

- (2) 250 amp Miller Syncrowave T.I.G. welder

- Spot welder 75KVA with CNC controls

- Spot welder 30KVA, rocker arm w/ CNC controls

- (2) Pro-weld model CD-212 Stud welder, 200V max.

- (2) Miller hand plasma torch

- Numerous overhead and Jib cranes

- Overhead welding boom

- Leak/pressure testing capabilities

Miscellaneous Fabricating

- New Haeger PEMserter Model 824 w/ Auto Feed and PEM insertion detection

- Haeger PEMserter Model 618

- Corner radius notcher 1/8” R. through 1” R. (1/4” capacity)

- 9” x 9” x 3/8” corner notcher

- (4) Drill presses with ‘Power Feed’ and ‘Auto-tapping’

- “Media” Blast System by Clemco – 12’ x 26’ x 10’ Media Blast Booth equipped for large scale parts

- Tumble Blaster

- Screen printing capability

Measurement and Testing

- Faro Arm portable coordinate measuring machine (CMM)

- 2 Trimos computerized height gauges

- Vast lineup of hand inspection equipment including: Calipers, pin gauges, protractors, micrometers, tape measures and much more

- Active gauge calibration control

- Certified Weld Inspector (CWI) on staff

General Equipment

- 20 cubic ft. vibratory finisher

- Complete cleaning and painting facilities

- Fully equipped tool room

- Large selection of unitized tooling

- (7) lift trucks to 8000 lbs. Capacity

- (5) 5 ton overhead cranes

Shipping

- 28 ft. Cargo Box Delivery truck

- 3/4 ton pickup with cap

- 5,000lb Capacity Transcell TC-2005 Scale

- (3) Lantech Stretch Film Wrappers

REQUEST A QUOTE TODAY:

Please fill out the form below to start your quote or give us a call at 262.251.4890RECENT ARTICLES

January 19, 2023

Mac Metal, a Wisconsin-based leading metal fabricator of high-quality weldments and metal products, has successfully obtained the ISO 9001:2015 certification of its Manufacture and Assembly of […]

March 9, 2022

Nearly four years ago, Mac Metal bought its first fiber laser – giving us the ability to cut a wide array of materials faster and with […]

July 24, 2018

If you’re in need of metal fabrication, it’s beneficial to learn the pros and cons of robotic and manual welding. They both have advantages and disadvantages, […]