Service Overview:

ROBOTIC & MANUAL WELDING

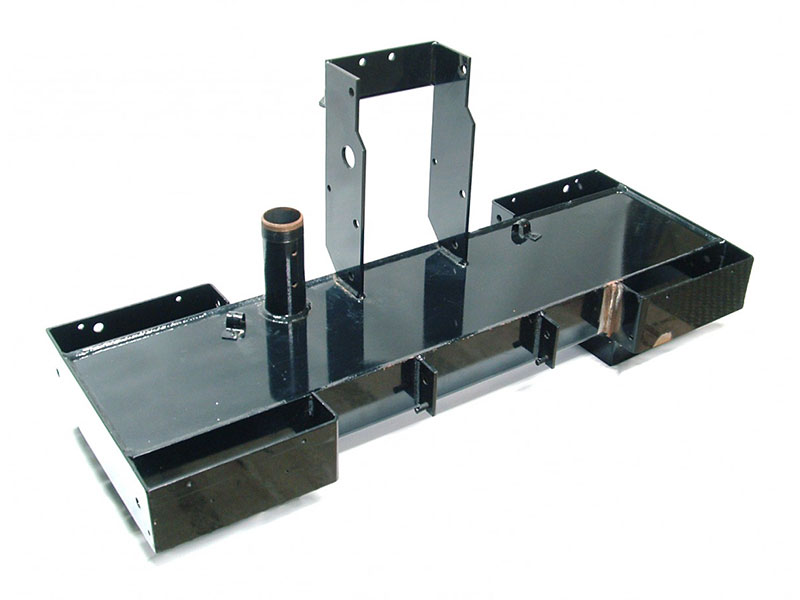

Creating a seamless weld is an art form – one our experienced team of AWS D1.1 certified welders take very seriously. Mac Metal has the flexibility and speed to deliver the precise, high-quality, one-piece appearance you require for your next steel, aluminum or stainless-steel project.

Our best-in-class, 40,000-sq.-ft. dedicated welding facility houses both manual and robotic welding operations. We can create large weldments through open-table and welding boom applications, with four overhead cranes to support heavier projects.

We're experienced with large and small fluid tanks, structural frames and weldments, and all projects are verified by one of our on-site Certified Welding Inspectors.

METALS AVAILABLE:

- Steel

- Stainless Steel

- Aluminum

EQUIPMENT:

- Wolf Robotics Leanarc 500C

- M.I.G. Welders

- T.I.G. Welders

- Spot Welders

- Stud Welders

- Hand Plasma Torches

- Multiple High Bay Gantry Cranes

- Modular Weld Fixturing

- Pressure and Leak Testing capabilities

- Grade Loading capability for large scale products

REQUEST A QUOTE TODAY:

Please fill out the form below to start your quote or give us a call at 262.251.4890RECENT ARTICLES

June 18, 2018

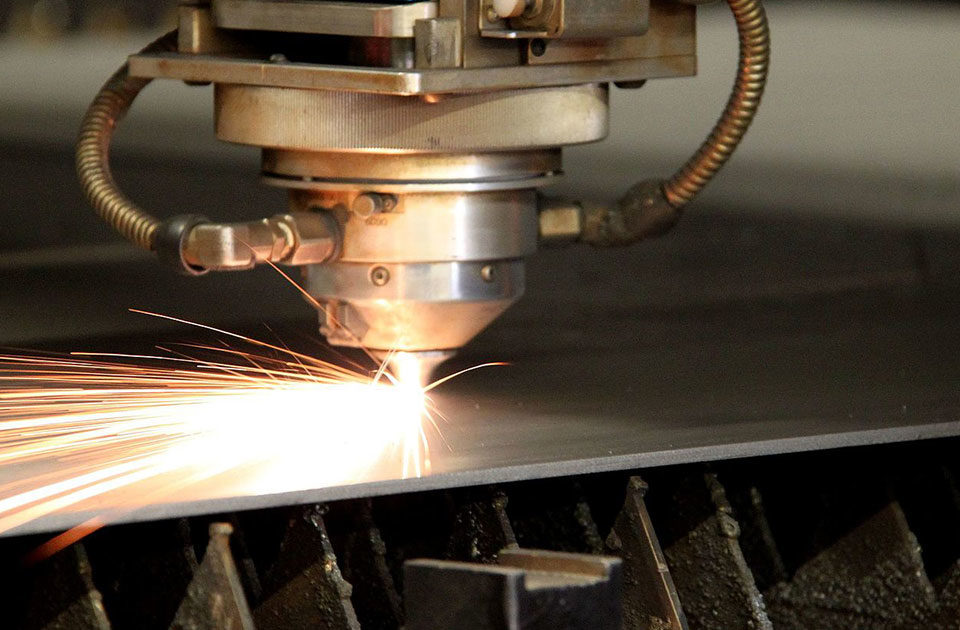

Mac Metal’s new fiber laser cutter has been in operation for several months now, providing high-quality metal cutting services to clients. But many industry professionals know […]

March 12, 2018

While it’s understandable that you may want to stay in-house with most of the manufacturing process, there aren’t many companies out there that handle their own […]

March 12, 2018

Mac Metal is constantly searching for ways to improve work efficiencies and product quality. Our latest investment is an Amada LCG 3015 AJ Series Fiber Laser, […]