- Give Us A Call Today

- 262.251.4890

Laser Cutting: Why We Chose Fiber Over CO2

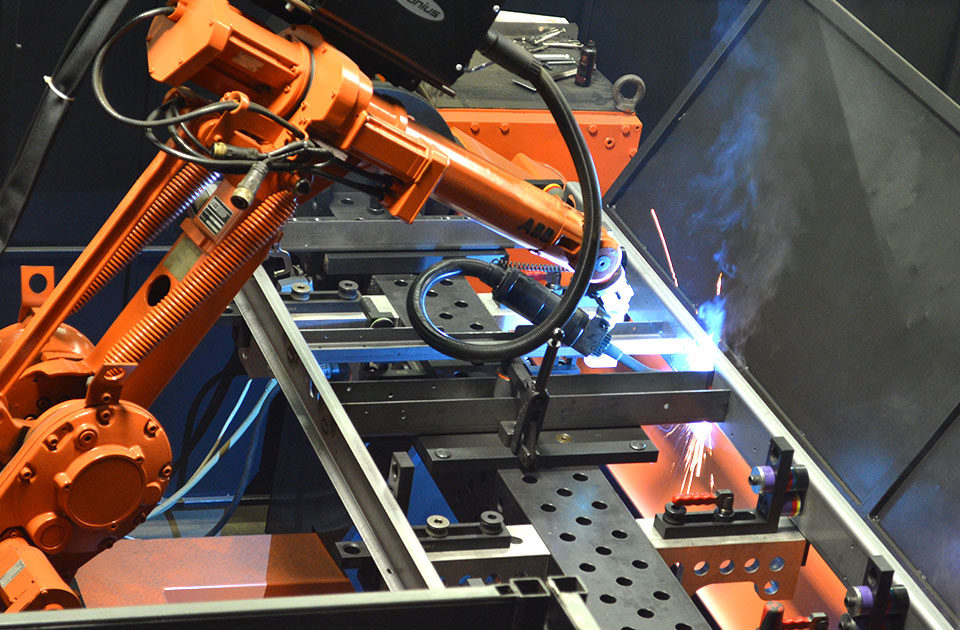

Mac Metal’s new fiber laser cutter has been in operation for several months now, providing high-quality metal cutting services to clients. But many industry professionals know there’s another option for laser cutting machines: CO2 laser cutters.

Mac Metal weighed the decision carefully and chose a fiber laser cutter over a CO2 one. Read on to learn more about the factors that went into the decision.

How Each Machine Work

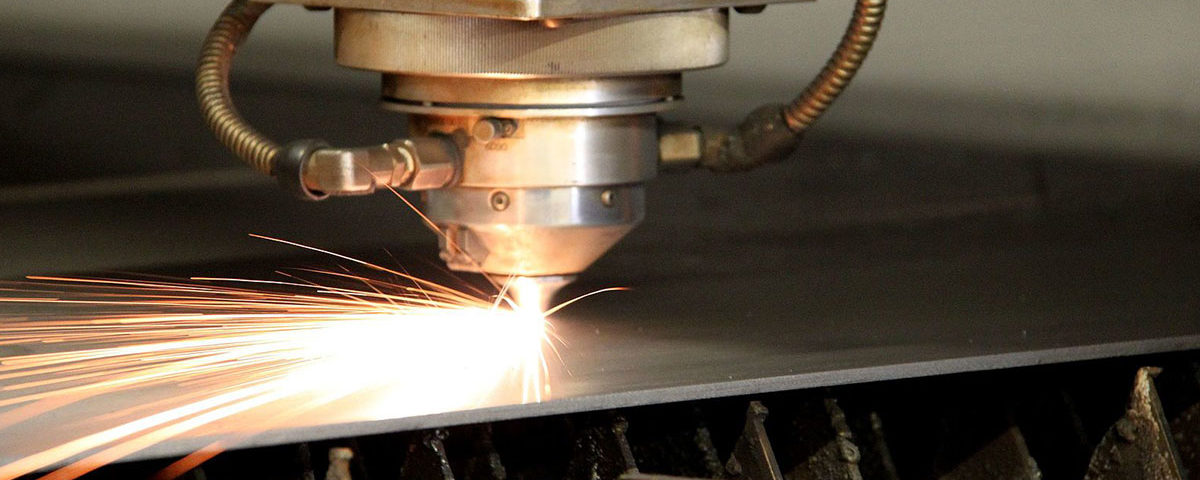

All laser cutters work by energizing and focusing photons into a laser, which is powerful enough to cut metal. The key difference between fiber laser cutters and CO2 cutters is in how the machine generates the laser.

CO2 laser cutters generate this laser in a tube of carbon dioxide gas. The machine introduces nitrogen into the tube, which collides with the CO2 molecules and releases photons (light particles). A device called a resonator combines these molecules and focuses them into a very hot, invisible beam of infrared light suitable for cutting metal.

Fiber laser cutters work by shining ordinary light into a fiber that’s treated with certain rare elements. (These exact elements will depend on the cutter’s design.) The rare elements absorb certain wavelengths of light, which results in extremely high-frequency light. Usually, the cutter runs the fiber directly to where the cutting beam emerges from the machine, although some cutters use mirrors to direct this light.

The Fiber Advantage

CO2 laser cutters have been favorites in the industry for many years. Fiber laser cutting technology is newer, but has many significant advantages over traditional cutters:

- Fiber cutters take up less space. CO2 cutters require gas storage tanks, pumps, and pipes. Fiber cutters are far more compact, by comparison.

- They’re more energy-efficient. CO2 cutters generate light — but they also generate a lot of heat, which is wasted energy. Keeping a CO2 cutter cool can be quite a chore. Fiber cutters generate far less heat, and don’t require chilling technology.

- Their operating costs are far lower. In addition to the machine’s high energy costs, a CO2 laser consumes both carbon dioxide and nitrogen gases. They also typically have high maintenance costs, due to the machine’s pumps, mirrors, and other moving parts. By contrast, a fiber laser cutter has far fewer moving parts, and no consumable materials — and Mac Metal passes those savings on to customers like you.

That’s why Mac Metal decided a modern fiber cutter would meet the needs of its customers far better than a CO2 cutter. Fiber laser cutters are compact, energy-efficient, and comparatively inexpensive to operate, and all of these characteristics are in-line with Mac Metal’s mission to provide top-notch services at a cost its customers can afford.

Quote Your Next Project with Mac Metal